If you were considering the purchase of a ceramic tile-cutting machine for your personal use at home, it would be worthwhile and desirable to have a Husky tile saw. Such a machine pays for itself in the long run. A husky tile saw makes for an efficient and convenient machine. End of the day, you will be pleased to have made a far better ceramic job.

Wet table tile saws are of immense use not only for making long straight cuts, but also for making minor and more elaborate cuts. With a wet tile saw around, you can easily do away with tile nippers in most of the cases.

In general a Husky table tile saws comprises of a direct drive motor that rotates a dull diamond studded blade. A small pan is housed below the table that acts as a basin for holding water. The blade rotates through the water, thus keeping it cool and helping the formation of a smooth clean cut on the ceramic tile.

The blade size of a wet saw may be 4 1/2", 7" or 10". An appropriate size for using the wet saw machine at home on your own would be 7". Similarly there is a variation of speed limits at which a wet saw operates: it varies from 3600 rpm to 5500 rpm (revolutions per minute.) For self operated machines a speed of 3600 rpm is enough.

An important feature of Husky tile saw is the capacity of the motor. Half hp (horse power) is ideal but for the normal jobs that you might be doing at home 1/3 hp should suffice.

Another feature you should ensure at the time of purchase is to check that its blade can be tilted / rotated to produce both beveled and mitered cuts. Model QEP 60087 Table Tile Saw - 7" Wet would make a first-rate choice for smaller ceramic tile jobs. If you are considering its use for handling larger ceramic tiles of the size of 12"x12" or bigger, you would better study Model MK Tile Saw Diamond 155779 MK-470 1/2 Horsepower 7-Inch Wet Tile Saw.

Most of the latest machines are provided with a built-in thermal overload protection mechanism in the form of a thermal relay. It protects the machine from getting overheated and burnt under conditions of continued sever torque. The relay actuates a circuit breaker that automatically switches off supply to the system. It further prevents you from restarting the machine till the motor has cooled down. Just check up that the wet saw you intend buying is provided with this safety built in feature.

Irrespective the model you choose, make sure that it is covered by warranty of at least one year.

Sunday, April 19, 2009

MK Tile Saw Buying Tips

If you were to buy a saw, you should know before hand the size of tile you are going to use. The smaller the tile, the lower is the capacity and hence the price. For small tiles of 8x8" you may have an MK Tile Saw, which uses a special angle grinder with a blade of 5-6". Now, that's a sturdy hard working machine but very noisy. Of course, there are experts who might use this machine even for cutting 16x16" travertine tile, but that would be a bit too much.

For 20x20" tile size you need a standard sized saw. But, for cutting diagonals of such a tile you have to use two operations, first you cut along half the diagonal and then turn the tile over to the other side and complete the cut across the diagonal. Dewalt makes a saw large enough to cut that sized diagonal in one operation only.

MK Tile Saw, Target, and Felker etc make first-rate saws but are very expensive and viable only if you are going to do a lot of tile work. Depending on the accessories you may opt, for a new Felker Tile Master would cost between $900-$1100. You may be lucky to buy a new decent saw for just $600 if one is on sale at the regular tile suppliers like Oregon Tile and Marble, or Intrepid.

At times one may find a good used saw. Look for the classifieds of popular newspapers or check up Craig's List. For small jobs of around 600 sq. ft., you might as well have it on rent. Check up with Star Rentals or any other equipment rental company. Perhaps Home Depot might rent wet saws too.

Be watchful of buying used saws:

Make it appoint to buy from reputable dealers only. Pawnshops sometimes have construction equipment but only the good ones will check if it's stolen. . If someone is selling a saw, find out why is he disposing it off. Someone going out of business and selling it is understandable but what if it were stolen or it might not work.

Have a trial before you pay.

Make sure that its blade works without much of wobbling. May be the seller already has a few broken pieces of tiles lying around. If for any reason the seller wouldn't let you try the machine, do not buy it. Invariably the pump of the old machines is not in working order. But that can be taken care of by spraying water thru a bottle or a hose to keep the blade cool. Make a few cuts to see that arbor is running fine and the motor too is o.k.

For 20x20" tile size you need a standard sized saw. But, for cutting diagonals of such a tile you have to use two operations, first you cut along half the diagonal and then turn the tile over to the other side and complete the cut across the diagonal. Dewalt makes a saw large enough to cut that sized diagonal in one operation only.

MK Tile Saw, Target, and Felker etc make first-rate saws but are very expensive and viable only if you are going to do a lot of tile work. Depending on the accessories you may opt, for a new Felker Tile Master would cost between $900-$1100. You may be lucky to buy a new decent saw for just $600 if one is on sale at the regular tile suppliers like Oregon Tile and Marble, or Intrepid.

At times one may find a good used saw. Look for the classifieds of popular newspapers or check up Craig's List. For small jobs of around 600 sq. ft., you might as well have it on rent. Check up with Star Rentals or any other equipment rental company. Perhaps Home Depot might rent wet saws too.

Be watchful of buying used saws:

Make it appoint to buy from reputable dealers only. Pawnshops sometimes have construction equipment but only the good ones will check if it's stolen. . If someone is selling a saw, find out why is he disposing it off. Someone going out of business and selling it is understandable but what if it were stolen or it might not work.

Have a trial before you pay.

Make sure that its blade works without much of wobbling. May be the seller already has a few broken pieces of tiles lying around. If for any reason the seller wouldn't let you try the machine, do not buy it. Invariably the pump of the old machines is not in working order. But that can be taken care of by spraying water thru a bottle or a hose to keep the blade cool. Make a few cuts to see that arbor is running fine and the motor too is o.k.

Thursday, April 16, 2009

Masonry Wet Tile Saw Blades

Lets talk little about the Masonry Wet Tile Saw Blades

A concrete block is a large rectangular brick used for civil construction. For higher density, sand and fine gravel is mixed with Portland cement. Lower density blocks use cinders instead of sand and fine gravel. Such blocks are called cinder blocks in the US and as breeze blocks or clinker blocks in the U.K. In clinker blocks, bottom ash or clinker is used. The blocks are built with hollow centers to reduce weight and get the added advantage of improved insulation.

These blocks can be glazed in different colors, thus making them water resistant. Such characteristics and the ease of layering, makes them a favorite of many architects. Another ease is that these can be cut to size by using masonry blades. These blocks find a wide application when moisture or sanitation issues are involved. It's an ideal choice for places like pools, shower stalls, car washes and locker room. These also find a wide application in commercial kitchens and dining areas like cafeterias as they impart brightness, being colored.

Masonry saw blades available in varying specifications are used to cut the blocks to size. Depending on the category, a masonry blade is used for cutting masonry tiles or stones. A wet tile saw tool is used for masonry blades. Water is necessarily needed to keep the blade cool and increasing its life.

A concrete block is a large rectangular brick used for civil construction. For higher density, sand and fine gravel is mixed with Portland cement. Lower density blocks use cinders instead of sand and fine gravel. Such blocks are called cinder blocks in the US and as breeze blocks or clinker blocks in the U.K. In clinker blocks, bottom ash or clinker is used. The blocks are built with hollow centers to reduce weight and get the added advantage of improved insulation.

These blocks can be glazed in different colors, thus making them water resistant. Such characteristics and the ease of layering, makes them a favorite of many architects. Another ease is that these can be cut to size by using masonry blades. These blocks find a wide application when moisture or sanitation issues are involved. It's an ideal choice for places like pools, shower stalls, car washes and locker room. These also find a wide application in commercial kitchens and dining areas like cafeterias as they impart brightness, being colored.

Masonry saw blades available in varying specifications are used to cut the blocks to size. Depending on the category, a masonry blade is used for cutting masonry tiles or stones. A wet tile saw tool is used for masonry blades. Water is necessarily needed to keep the blade cool and increasing its life.

Labels:

saw,

saws,

Tile saw,

tile saw blades,

tile saws,

Wet tile saw

Wednesday, April 15, 2009

Granite Tile Saw Blades Guide

Granite, a very trendy material of floorings and countertops is the hardest of stones and is available in a variety of colors. Cutting of granite counter tops requires a tile saw that might have a granite blade or a diamond tile saw blades. Cutting of larger slabs involve a larger tile saw like a Track Saw

At an affordable price, the durable granite blades offer a very viable proposition for cutting of a variety of stones. For instance a continuous smooth rim granite blade is opted for smoothest cut in ceramic tiles or decorative stones whereas segmented blades are used most often when chipping is not an issue.

The high-performance design of our continuous smooth rim granite blade is devised to offer a long life while ensuring a chip-free cutting. For cutting of hard stones such high-speed blades utilize water to keep the temperatures down. For cutting of marble, ceramic tile, and natural stone a high-quality general-purpose granite blade is needed. These blades can also be used to profile the edges of marble or granite.

A wet tile saw is the preferred choice of most of the professionals. A granite blade operating at high speeds of 2800 rpm cuts stone, marble and granite at various depths and angles of 45o and 90 o.

At an affordable price, the durable granite blades offer a very viable proposition for cutting of a variety of stones. For instance a continuous smooth rim granite blade is opted for smoothest cut in ceramic tiles or decorative stones whereas segmented blades are used most often when chipping is not an issue.

The high-performance design of our continuous smooth rim granite blade is devised to offer a long life while ensuring a chip-free cutting. For cutting of hard stones such high-speed blades utilize water to keep the temperatures down. For cutting of marble, ceramic tile, and natural stone a high-quality general-purpose granite blade is needed. These blades can also be used to profile the edges of marble or granite.

A wet tile saw is the preferred choice of most of the professionals. A granite blade operating at high speeds of 2800 rpm cuts stone, marble and granite at various depths and angles of 45o and 90 o.

Ceramic Tile Saw Introduction

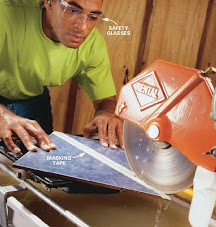

Ceramic tiles being thick and brittle, cannot be cut properly by ordinary circular saws. Wet tile saws are used for cutting ceramic tiles. The oncoming of the wet tile saw brought around a real change in the cutting of such tiles. A wet tile saw doesn't get heated, and uses a relatively dull tile saw blades with no serrations. Its portability makes it an ideal choice for being used at sites.

A wet tile saw first grinds a channel through the tile. Then a blunt, wide, non-serrated blade with sharp sand crystals or diamond is used for cutting, thus getting a clean, smooth edge. Such saws are convenient to trim tiles at the installation site to fit neatly at the corners of a room or to set the tiles in innovative patterns. Such saws are water cooled to avoid them from getting heated

A hand tile cutter works the fastest for cutting of ceramic tiles. The tile is supported on a padded bed. Keeping the saw handle pressed down firmly, the titanium wheel is rolled along the tile to get desired impression on its surface. On pressing the handle again on the marked impression, the tile breaks evenly across the desired line. This technique doesn't offer accurate cuts.

Heavy-duty ceramic tile saws available for cutting extra hard and dense domestic tiles are equipped with large cutting wheels and suitable handle carriages.

A wet tile saw first grinds a channel through the tile. Then a blunt, wide, non-serrated blade with sharp sand crystals or diamond is used for cutting, thus getting a clean, smooth edge. Such saws are convenient to trim tiles at the installation site to fit neatly at the corners of a room or to set the tiles in innovative patterns. Such saws are water cooled to avoid them from getting heated

A hand tile cutter works the fastest for cutting of ceramic tiles. The tile is supported on a padded bed. Keeping the saw handle pressed down firmly, the titanium wheel is rolled along the tile to get desired impression on its surface. On pressing the handle again on the marked impression, the tile breaks evenly across the desired line. This technique doesn't offer accurate cuts.

Heavy-duty ceramic tile saws available for cutting extra hard and dense domestic tiles are equipped with large cutting wheels and suitable handle carriages.

Granite Tile Saw Blades Introduction

Granite tile saw blades are ideal for cutting granite slabs or tiles.

Compared to marble, these days, granite is finding a wider acceptance for flooring and countertops because of its hardness and economical prices.

Its availability in abundance and speedier cutting by using granite tile saw blades, further helps its popularity.

Granite is compounded of four minerals: quartz, feldspar, mica, and hornblende. The natural variations of these minerals impart granite its different natural colors and patterns.

Available architectural and archeological evidences suggest it was being used for building columns, jambs, and wall or floor veneer even around 26B.C. Red Pyramids of Egypt are a testimony to that.

Granite tiles are a common sight at public places like hotel lobbies, washrooms, kitchen countertops and shopping malls. A wide variety of colors and patterns have made it a favorite of architects for designing aesthetic interiors. Polished granite is desired for countertops due to its sturdiness and attractive polished look.

Because of the hardness and cost, cutting of tiles need a careful and skilled handling.

The process of cutting the edges to the needed size involves the application of masonry or a tile saw. Nevertheless, easy availability of granite blade in a wide variety of specifications helps to speed-up the cutting process.

For cutting precious tiles, a wet tile saw prevents breakages and losses. Latest models of tile saws are equipped with all the gears and accessories to attain accurate cuts of different types with much ease.

Compared to marble, these days, granite is finding a wider acceptance for flooring and countertops because of its hardness and economical prices.

Its availability in abundance and speedier cutting by using granite tile saw blades, further helps its popularity.

Granite is compounded of four minerals: quartz, feldspar, mica, and hornblende. The natural variations of these minerals impart granite its different natural colors and patterns.

Available architectural and archeological evidences suggest it was being used for building columns, jambs, and wall or floor veneer even around 26B.C. Red Pyramids of Egypt are a testimony to that.

Granite tiles are a common sight at public places like hotel lobbies, washrooms, kitchen countertops and shopping malls. A wide variety of colors and patterns have made it a favorite of architects for designing aesthetic interiors. Polished granite is desired for countertops due to its sturdiness and attractive polished look.

Because of the hardness and cost, cutting of tiles need a careful and skilled handling.

The process of cutting the edges to the needed size involves the application of masonry or a tile saw. Nevertheless, easy availability of granite blade in a wide variety of specifications helps to speed-up the cutting process.

For cutting precious tiles, a wet tile saw prevents breakages and losses. Latest models of tile saws are equipped with all the gears and accessories to attain accurate cuts of different types with much ease.

Ceramic Tile Saw Installing Tricks

The process and technique of installing ceramic tile saw is the same, be it a floor, walls or a counter top. With the right equipment and the basics you can do almost any tile project. Here's all that you need for a tile project.

1.Tools

The basic tools are listed here. You might already be having a few of these.

* Plastic Buckets of 5 gallons

* Ceramic Tile Nippers

* Tile Cutter Board

* Hammer

* Screwdriver

* Notched Trowel

* Margin Trowel

* Chalk Line

* Pencils

* Tri Square

* Spacers

* Tape Measure

* Level

* Tile Sponge

* Tile Saw

2. A Solid Base

Many kinds of surfaces can be used as a base, but the mounting surface needs to be solid. Old linoleum or an old tile or concrete is fine. Generally cement board "Hardibacker" gives best results. It's rigid and adhesives stick to it just right.

3. The Right Adhesive

The pros use a masonry product called "Thinset". This can be made wet. You may use a pre-mixed adhesive with latex.

4.Careful With Spacing

For excellent finish the tile must be set evenly with consistent spacing. By making use of plastic spacers you can maintain consistency of space between the tile saws. Part of the fun of laying tile is keeping it straight and leveled, though the tile size varies a little from tile to tile.

5. Grout Right

After the tile is set and dried in place, you need to fill the spaces with grout. Depending on the size of the spaces between the tiles, you may use grouts with a sand content or those with latex for improved performance. For kitchens and bathrooms you may use epoxy grout that is waterproof and stain proof.

1.Tools

The basic tools are listed here. You might already be having a few of these.

* Plastic Buckets of 5 gallons

* Ceramic Tile Nippers

* Tile Cutter Board

* Hammer

* Screwdriver

* Notched Trowel

* Margin Trowel

* Chalk Line

* Pencils

* Tri Square

* Spacers

* Tape Measure

* Level

* Tile Sponge

* Tile Saw

2. A Solid Base

Many kinds of surfaces can be used as a base, but the mounting surface needs to be solid. Old linoleum or an old tile or concrete is fine. Generally cement board "Hardibacker" gives best results. It's rigid and adhesives stick to it just right.

3. The Right Adhesive

The pros use a masonry product called "Thinset". This can be made wet. You may use a pre-mixed adhesive with latex.

4.Careful With Spacing

For excellent finish the tile must be set evenly with consistent spacing. By making use of plastic spacers you can maintain consistency of space between the tile saws. Part of the fun of laying tile is keeping it straight and leveled, though the tile size varies a little from tile to tile.

5. Grout Right

After the tile is set and dried in place, you need to fill the spaces with grout. Depending on the size of the spaces between the tiles, you may use grouts with a sand content or those with latex for improved performance. For kitchens and bathrooms you may use epoxy grout that is waterproof and stain proof.

Labels:

ceramic tile saw,

ceramic tile saws,

saw,

saws,

Tile saw,

tile saws

Tile Saw Introduction

Tile saw products are becoming so popular that it's difficult to imagine a present day house being made and finished without their use. Easy availability in a variety of colors and patterns make granite tile saws an ideal choice for having bright and aesthetically designed interiors.

Marble, having been used since centuries, competes with granite for its beauty. Apart from being an excellent medium for sculpture and art, its rich luster and light color, coupled with its cooling effect encourages its use as a flooring material and washroom applications.

Followed by granite and marble are ceramic tile saws. Being non-porous and hard these last long. Compared to other mediums it's economical and hypoallergenic, the characteristics ideally needed for places prone to gems and bacteria.

That's why you see them so often in kitchens, countertops and washrooms. The polished surface of ceramic tile saw is helpful in keeping away dust, dirt and allergens.

Cutting of tiles to suit the imaginations of an architect or an artist necessitates the use of a tile saw. Tile saws are available in a variety of specifications to suit varying needs of designers. Wet tile saws are very popular. These tile saws incorporate a cooling mechanism that keeps the tiles cool, as excessive heat generated while cutting might damage the tiles.

Such tile saws are equipped with diamond cutting blades. When chipping is not a problem, dry tile saws may be used. Tile saws may be operated by electric or gas power. Smaller models of tile saws need blades of 8-10" whereas cutting of larger tiles and slabs require power driven tile saws.

Marble, having been used since centuries, competes with granite for its beauty. Apart from being an excellent medium for sculpture and art, its rich luster and light color, coupled with its cooling effect encourages its use as a flooring material and washroom applications.

Followed by granite and marble are ceramic tile saws. Being non-porous and hard these last long. Compared to other mediums it's economical and hypoallergenic, the characteristics ideally needed for places prone to gems and bacteria.

That's why you see them so often in kitchens, countertops and washrooms. The polished surface of ceramic tile saw is helpful in keeping away dust, dirt and allergens.

Cutting of tiles to suit the imaginations of an architect or an artist necessitates the use of a tile saw. Tile saws are available in a variety of specifications to suit varying needs of designers. Wet tile saws are very popular. These tile saws incorporate a cooling mechanism that keeps the tiles cool, as excessive heat generated while cutting might damage the tiles.

Such tile saws are equipped with diamond cutting blades. When chipping is not a problem, dry tile saws may be used. Tile saws may be operated by electric or gas power. Smaller models of tile saws need blades of 8-10" whereas cutting of larger tiles and slabs require power driven tile saws.

Tuesday, April 14, 2009

Privacy Policy

We do not use cookies to track your online activity and do not even try to capture any of your information. This site is meant to be anonymous and we will strive to keep it that way.

No need to worry about the selling or sharing of your information because we don’t even try to capture it.

No need to worry about the selling or sharing of your information because we don’t even try to capture it.

Terms And Conditions

We will provide the best information possible here, but you are responsible to do your own research before taking any action. We will not be held liable for anything that happens from the use of information here.

About

Tile Saw Guide was established in 2009 to help you to learn about Tile Saw. Tile Saw Informations can increase your quality of life and this site is meant to help you in your journey.

Subscribe to:

Posts (Atom)